Ka tloaelo e bulehileng e pepesitsoeng vratic solonod sov16-21

Lintlha

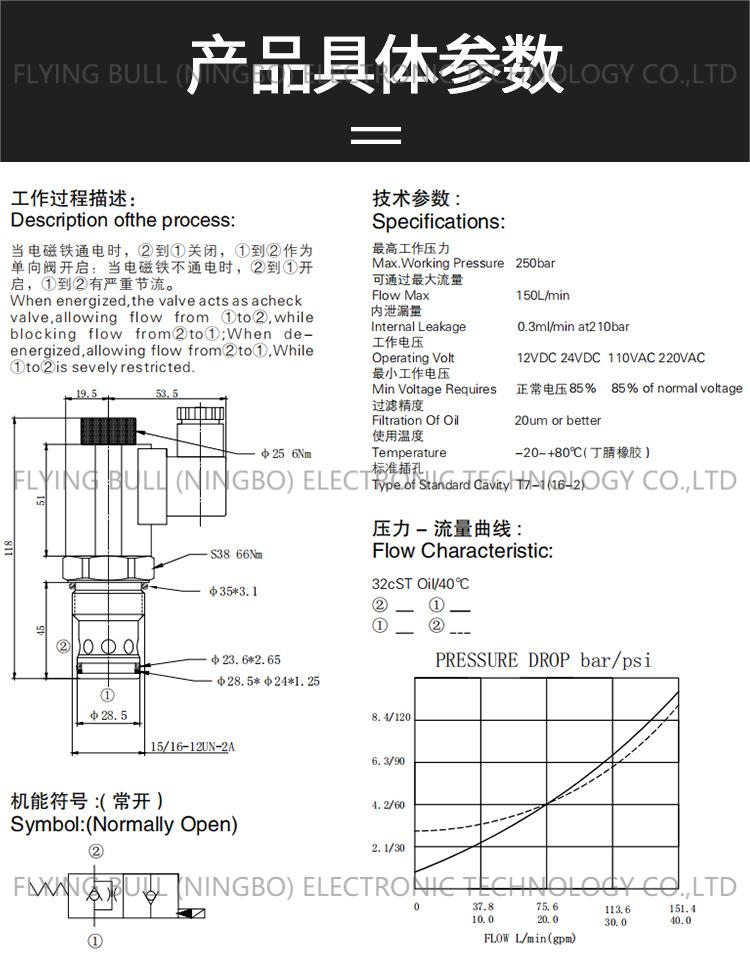

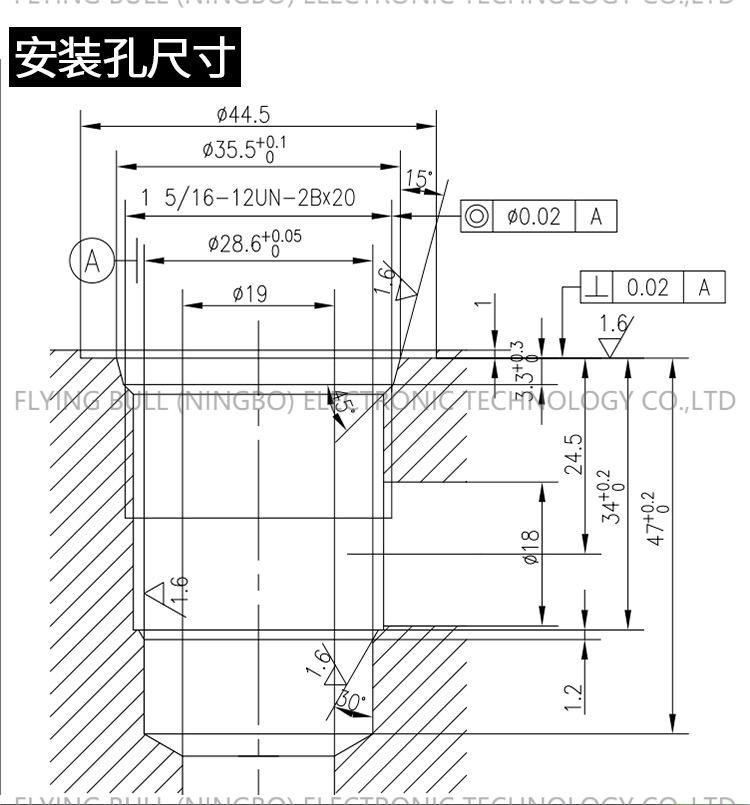

Mahlong a Bohlokoa:Mokhoa o tobileng oa 'mele oa Valve

Tikoloho ea Khatello:khatello e tloaelehileng

Tikoloho ea mocheso:ngoe

Tataiso ea ho phalla:One Way

Lisebelisoa tsa boikhethelo:'Mele oa Valve

Mofuta oa drive:Matlafatsoa

E sebetsang:Lihlahisoa tsa Petroleum

Lintlha tsa tlhokomelo

Valve e koetsoeng e sotlehileng

Valve e nang le lits'oants'o tsa mantlha ke motho oa mantlha ea omaaneng e sebelisitsoeng ho laola tataiso ea mokelikeli, oa sehlopha sa litlaleho; Hangata e sebelisoa ka taolo ea mochini le li-valves tsa indasteri ho laola tataiso ea mahareng, e le hore a laole switch ea valve.

Ho na le sekoti se koetsoeng ka linakong tse peli tse tsoang, ka masoba ka maemo a fapaneng. Hole e 'ngoe le e' ngoe e lebisa liphaepheng tse fapaneng tsa oli. Ho na le valve bohareng ba mokokotlo le li-elektronegne tsa motlakase ka mahlakoreng ka bobeli. Ha makenete a lefisoa ka lehlakoreng lefe a matlafalitsoeng, 'mele oa liphoofolo o tla khahlisoa ke lehlakore lefe. Ka ho laola ts'ebetso ea mmele oa li-toime, likoti tse fapaneng tsa oli li tla tsamaisoa ke khatello ea oli, 'me seliba sa oli se tla tsamaisoa ke khatello ea oli ho sisinyeha. Ka tsela ena, mokhatlo oa mochini o laoloa ka ho laola taolo ea hona joale ea elektronet.

Li-vaereishene tsa cartridge li sebelisoa haholo ka har'a mochini oa kaho le ka mokhoa o hlakileng, e leng koluoa e tšepahalang, e joalo, lerata le ho ntlafatsa ka ho ts'epahala. Likarolo tsa bohlokoa tsa li-valeridge tsa Carridge tse hlahisitsoeng ke k'hamphani ea rona li qhalana kapa li ts'oaroe ke tšepe ea boleng bo holimo ho netefatsa bophelo bo bolelele ba ho sebetsa.

1.DDELITONEEETSI, 2. Ho ba le lekunutu, ho tlosa lipelaelo tse potlakileng tsa bareki, tse 11. Ho fana ka tlhahiso-leseling.

Tlhaloso ea sehlahisoa

Lintlha tsa Khamphani

MOLEMO OA KOTSI

TS'ELISO

LBH