Litokisetso tsa Pneumatic li bapala karolo ea bohlokoa indasteri ka ho e kopanya le ho ntlafatsa lits'ebetso tsa Pneimatic. Lits'ebeletso tsa bona tsa bohlokoa tsa bahlabante tse kang lihlahisoa, bophelo bo botle le Aerospace. Kholo ea mmaraka e bontša ho eketsa mesifa le matla a sebetsang. Ho hloka tsebo, joalo kaSehonyi sa likoloi sa metsi sa metsi sa koloi sa likoloi tsa koloi ea likoloi tsa koloi h034-2, e be le mohlala, mohlala oa kamoo lithapo tsa khale li kopanelang ho etsa litlhoko tsa indasteri.

Key Picaways

- Sebelisa litsamaisong tsa limela tsa limela tsa ho beha leihlo le ho lokisa. Ho lieha ho hoholo le ho eketsa katleho ea mosebetsi.

- Khetha likhetho tse tala tse tala ho boloka matla le ho thusa polanete. Meetso e metle e ka fokotsa likoloto tsa matla ka 20%.

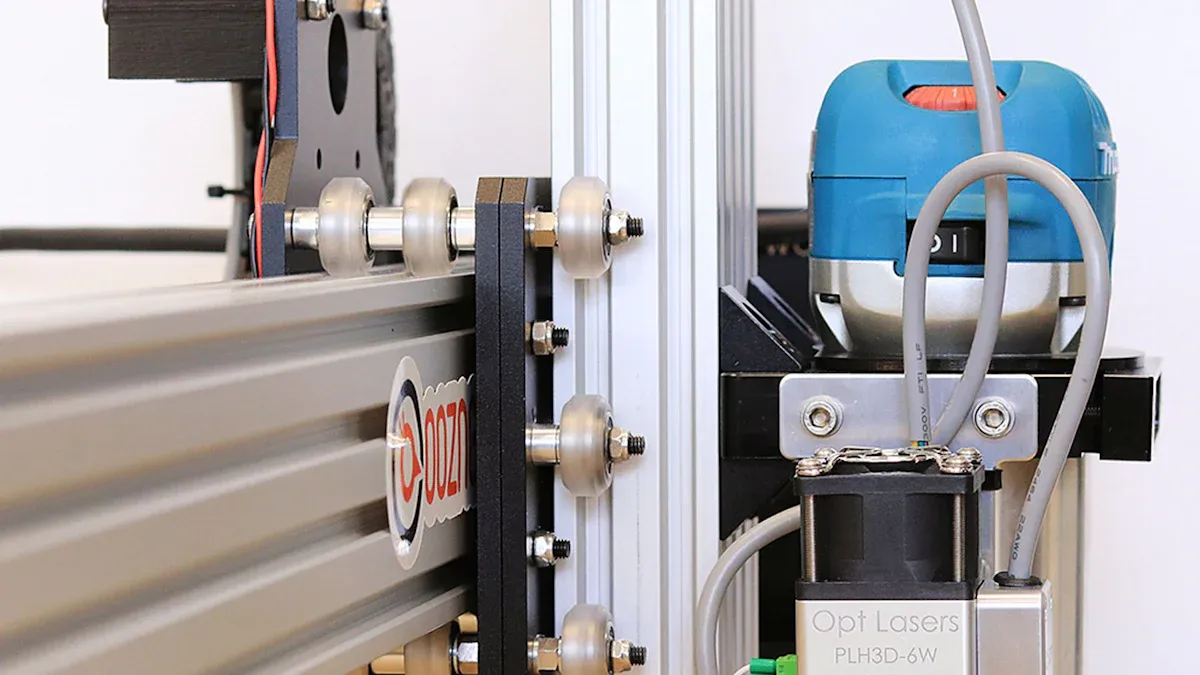

- Khetha likarolo tse nyane tsa pneumatic ho boloka sebaka 'me u sebetse hamolemo. Likarolo tsena li khothalletsa ho nepahala ebile li bohlokoa haholo bakeng sa liroboto le tsa bophelo bo botle.

Smart PoneMatic Sistimi ea Smart le IOT

Litsamaiso tse hokahaneng tsa PNanetic

Ho phahama ha lits'ebeletso tsa semmuso tse hokahaneng li sebelisitsoe lits'ebeletso tsa indasteri. Ka ho kopanya khokahano e se nang mohala le protocol tse tsoetseng pele, litsamaiso tsena li thusa data ea data e se nang thuso lipakeng tsa likarolo. Mohlala, Sehlekehleke sa AMS se bonts'a hore na theknoloji e se nang mohala e ntlafatsa ho fetoha le maemo ha ho kenya ts'ebetso le ho ntlafatsa ts'ebetso ea tsamaiso ka kakaretso. Khokahano e boetse e lumella lintlha tsa lintlha tsa sesebelisoa, li fana ka litlhahlobo tsa nako ea nnete le licheke tsa bophelo bo botle. Bophahamo hona bo tiisa hore mathata a ka ba teng pele a ngoloa pele ba eketseha, haholo ha ba ntse ba lokolla tlhahiso le ts'ebetso ea ts'ebetso.

Tlhokomelo ea nako ea 'nete le tlhokomelo e boletsoeng esale pele

Ho beha leihlo la nnete ke litsamaiso tsa sejoale-joale tsa sejoale-joale. Ka li-sensor tse matla tse matla-li-Iota tse nang le matla - litsamaiso tsena li ntse li tsoela pele ka litšoantšo tse thata tsa meralo, tse kang khatello le litefiso. Lintlha tsena li tšehetsa tlhokomelo e reriloeng esale pele, e thibelang nako e sa tsebeng ho tseba litaba tse kang likhechana kapele. Ho ea ka pono ea indasteri, tlhokomelo e boletsoeng esale pele e ntlafatsa litšenyehelo tsa ho lokisa, e ntlafatsa boleng ba sehlahisoa, hape e fokotsa litekanyetso. Mohlala, litemoso tsa pejana tsa lisebelisoa li hlōla ts'ebetso ea ho etsa lintho le ho fokotsa litšila, ho etsa mesebetsi e tsitsitseng hape e theko e boima.

| Rua molemo | Tlhaloso |

|---|---|

| Phokotso ea litšenyehelo | E thibela tšenyo ea kahlolo e 'ngoe ho li-afdown, litšenyehelo tsa ho fokotsa litšebeletso. |

| Boleng bo ntlafalitsoeng ba sehlahisoa | E felisa lihlahisoa tse nang le phoso ka liphoso tse patiloeng tse thata ho li bona. |

| O ntlafalitse katleho | Ho hlahisa litemoso tsa pele tsa ho hloleha ho beleha, ho ntlafatsa ts'ebetso e akaretsang ea ho hlahisa. |

| Liphetoho tse fokotsehileng | E eketsa katleho le ho fokotsa litšila ts'ebetsong ea ts'ebetso. |

| Phokotso ea litšenyehelo tsa Tlhokomelo | E fokotsa khafetsa le ho bitsa chelete ea ho hlokomela bana ba pelehi. |

Lisebelisoa tsa IOOT-EMPANG PNETAM

Khokahano ea IOOOT e eketsehile lits'ebetso tsa likopo tsa limpho tsa Pneumatic ho theosa le indasteri. Litsebi tsena tse bohlale li bapala karolo ea bohlokoa ho mananeo a ntlafalitsoeng a data. Ka ho fana ka data ea sensor ea 'nete, ba nolofalletsa basebetsi ho rera ho hlokomela le ho arabela litabeng hang-hang. Mokhoa ona ha o ntlafatse katleho ea lisebelisoa empa hape o etsa hore lits'ebetso tse sa tsitsang. Liindasteri tse kang tsa indasteri le tsa bophelo bo botle haholo tsoeloseng tsena, ha li ntse li tsamaea ka sistimi e hlakileng le e sebetsang ho boloka litekanyetso tse phahameng tsa ts'ebetso.

Katleho ea matla le ts'ebetso

Litharollo tsa Eco-Mafika

Tharollo ea Eco-Phatomate e nang le maemo a feto-fetohang ea ho fetola indasteri ka ho fokotsa tšusumetso ea tikoloho le ho khothaletsa mekhoa e tsitsitseng. Lisebelisoa tse sebetsang hantle tsa sintimate li fokotsa moea, e ka fokotsang matla a lahlehileng ka 10% ho 20%. Ntlafatso ena ha e bolele matla empa e boetse e tšehetsa lipakane tsa tlhokomelo ea khoebo. Mahlale a tsoetseng pele, a kang lisebelisoa tse matla tsa khohlano, a fokotsa thepa, a ntlafatsa ts'ebetso ea matla. Lipolelo tsena li kenya letsoho phokotsong e kholo ea khatiso ea carbon, a ikamahanya le boiteko ba taolo ea lefatše. Ka ho amohela litharollo tsa Eco-letšoao le nang le botsoalle ba eco

Meetso ea Ts'ebetso ea Matla

Merero ea meralo ea matla lipelong tsa Pettems e shebisisa ts'ebetso e fetolang ts'ebetsong ha u nyenyefatsa. Mohlala, ho fokotsa maemo a khatello le ho tlatsa litloaelo tsa ho phallela ho phalla ka bongata, a lebisang ts'ebetsong e sebetsang haholoanyane. Livideo tsa PNEUMMAM Finandight, tse tsejoang ka hore bo sireletsehe le bokhoni ba tsona ba ho thibela mafu a sefofane, re bapale karolo ea bohlokoahali ho meralo ena. Ho feta moo, tsoelo-pele ea theknoloji ea theknoloji ea theknoloji le lifilimi li ntlafalitse katleho ea matla ho likarolo tse fapaneng. Mohlala, complifugal Compressors e fihlela litefiso tsa katleho ea ho fihla ho 63.4%, ha basebelisi ba morao ba sebetsa ka mokhoa o tsotehang 99%. Litsie tsena li tiisa hore litsamaiso tsa secneimatic li lula li le botsoalle bo bokae.

Melemo ea Litlaleho tsa Ts'ebetso ea Tšehemolohi

Ho Tšehetsoa Maemong a Tlhaho tsa Pentic ho fana ka melemo ea litšenyehelo tse kholo ea ts'ebetso ea ts'ebetso. Ka ho bua ka ho bua ka mokhoa o tsitsitseng, joalo ka ho tsoaloa ha moea, lik'hamphani li ka fokotsa tahlehelo ea matla ho fihlela 20%. Sena se fetolela ho fokotsa likoloto tsa matla le liphetoho tsa khafetsa tsa lisebelisoa. Meetso ea tsamaiso e sebetsang e sebetsa le ho ntlafatsa ts'ebetso ea mochini, ho fokotsa litšenyehelo tsa ho phomola le ho fokotsa litšenyehelo tsa ho lokisa. Ntle le moo, mekhoa e matla e matla, e kang ho sebelisa thepa e tšoarellang le mahlale a boloka matla, sephetho sa chelete ea nako e telele. Indasteri e nepahetseng ea pele ho ts'ehetso ha e na litšenyehelo tsa ho fokotsa feela empa hape e boetse e ntlafatsa tlholisano ea bona ea mmaraka ka ho bontša boitlamo ba tikoloho.

Miniturization le merero e kopanetsoeng

Tlhokahalo ea li-fitlings tse nyane tsa pneumatic

Tlhokahalo ea litlolo tse nyane tsa pneumatic e ntse e hola e le indasteri e le indasteri e lebisang mekhoa e nang le kopanelo le e sebetsang. Australiation Automation e tsamaisitse mokhoa ona oa mofuta ona, ka li-bahlahisi ba batlang boqapi le lipehelo tsa polokeho ho tsosa lits'ebetso. TheHo loketse ho loketsengMmaraka o supa phetoho ena, kaha likarolo tse kopanetsoeng li thusa ho kenya ts'ebetso le boima ba tsamaiso. Tsoelo-pele tsena tsa tsoelo-pele ho indasteri joaloka liroboto le elektroniki, moo mathata a sebaka le ho nepahala a bohlokoa.

Likopo tsa meralo ea compact

Li-fitting tsa pneumatic li fumana lits'ebetso lipelong tse fapaneng tse hlokang ts'ebetso e phahameng libakeng tse fokolang. Liroboto, melemo ea melemo e tsoang ho meralo ena ka ho fihlela maemo a fetelletseng le ho nepahala ho tsamaea. Ka mokhoa o ts'oanang, lisebelisoa tsa bongaka, joalo ka lisebelisoa tsa bongaka le lisebelisoa tsa ho buoa, li itšetleha ka lintho tse tsamaeang ka mokhoa o tšoanang ntle le ho sekisetsa. Matla a sebetsang a matla a ntlafatsa boipiletso ba bona:

- Ho emisa ho emisa hore moea o fokotsa matla a lahlehileng ka 10% ho 20%.

- Ho kopanya thibelo ea Leazage e nang le meralo e bohlale e khothaletsa poloko e matla ho isa ho tse tšeletseng.

- Litšitiso tse matlafatsang moea, tse kang ho otla, ho fihlela katleho e phahameng ha ho bapisoa le lits'ebetso tsa mechini.

Melemo ena e etsa hore maisi a khotsofalo a bohlokoa haholo ho indasteri e shebileng ho matlafatsa tlhahiso le ho tsilatsila.

Mathata ho Miniaturization

Leha e le Melemo,, ho fana ka mefuta ea li-minutuaturistion. Lipeke tse nyane li hloka mekhoa e metle ea tlhahiso, e ka eketsang litšenyehelo tsa tlhahiso. Ho feta moo, ho boloka ho tšoarella le ts'ebetso ha ba rera ho ts'oara lisebelisoa le boenjiniere. Ho netefatsa hore ho lumellana le litsamaiso tse teng le tsona li beha mathata, joalo ka likarolo tse nyane li ka hloka lisebelisoa tse khethehileng kapa li-adapters. Ho hlola mathata ana a bohlokoa bakeng sa ho hlokomela ka botlalo e ka khona ho ba le mekhoa ea sineime e meholo ka botlalo.

Lisebelisoa tse tsoetseng pele le mekhoa ea ho fana

Lisebelisoa tse bobebe le tse tšoarellang

Tsoelo-pele e nang le thepa e bobebe le e tšoarellang e ntlafalitse tšebetso haholo ts'ebetso le ho ts'epahala ha ts'ebetso le ho ts'epahale ha liketsahalo tsa pneumatic. Likotsi tse phahameng tsa tšebetso, tse kang polymers tse tsoetseng pele, li sireletsa khahlanong le ho rorisoa le mokhosisi ha u ntse u fokotsa likhohlano. Likotsi tsena li ntlafatsa nako e telele ea ho bapala, e li etsa hore li lokele libaka tsa ho batla indasteri. Ntle le moo, meralo e mengata e ncha, ho kenyelletsa le mekhabiso ea khatello le li hokahane, ho ts'oaroa ha bobebe le ho nolofatsa lits'ebetso tsa ho kenya.

| Mofuta oa tsoelo-pele | Tlhaloso |

|---|---|

| Likooa tse phahameng tsa Ts'ebetso | Polymis e tsoetseng pele e fana ka tšireletso khahlanong le ho rorisoa, ho sisinyeha le ho ntlafatsa ts'ebetso ka ho fokotsa likhohlano. |

| Meetso ea Bochabela | Likarolo tse kang tsa puseletso tsa to-to-ho hokahanya mekhabiso le meralo ea mekhabiso e ntlafatsang ho kenya le ho boloka litlhoko tse bobebe. |

Khokahano ea lisebelisoa tsena li tiisa hore ho betla matheba a PNEMAciaciaciaciatic ho lula ho le matla le ho sebetsa hantle kapa likopo tse phahameng tsa mocheso.

3D khatiso ea 3D ka li-finematic li-fittings

Khatiso ea 3D e fetotse tlhahiso ea li-twumatic tse tsamaeang ka potlako le tloaelo. Theknoloji ena e lumella bahlahisi ho theha li-goometo tse rarahaneng tse neng li sa khonehe ka mekhoa ea setso. Mohlala, ho fumana matsoele a 3d-ho hatisoa ho kenyelletsa liteishene tse ka hare bakeng sa moea o futhumetseng oa moea o ntlafalitsoeng, o ntlafatsa ts'ebetso ea tsamaiso. Ts'ebeliso ea lisebelisoa tse bobebe, tse kang polymers tse tsoetseng pele, li fokotsa boima ba likarolo ntle le ho sekisetsa ho sekisetsa. Indasteri e kang aerospace

Melemo e Ikarabellang ea indasteri

Lisebelisoa tse tsoetseng pele tse itlama ka mekhoa ea Pneumatic li fana ka melemo ea meputso e fapaneng. Ka li-intomation le liroboto, thepa e bobebe le e hanyetsanang e ntlafatsa ts'ebetso le ho ts'epahala. Li-com-to-li-mechanisms tsa ho hokahana le li-coflings tse potlakileng li fokotsa nako ea nako, tlhahiso e ntseng e eketseha libakeng tse fanang ka thepa. Litsebi tsa mahlale a bohlale li kopantsoe le litlolo tsa nako ea 'nete, ts'ebetso ea ho ntlafatsa le litšenyehelo tse tlase tsa ts'ebetso. Likarolo tsena li etsa hore li-finematic li be le li-indasteri tsa indasteri e hlokang ho nepahala le ho sebetsa hantle.

- Lithapelo tsa Mopheko-lipakeng li ea ho rarolla litharollo tse kopanetsoeng le tse bobebe, tsa bohlokoa bakeng sa li-approspace le lits'ebetso tsa koloi.

- Likarolo tse kang li-copling tse potlakileng li ntlafatsa mokhoa oa ho itšupa le ho fokotsa nako ea ho lokisa.

- Bolaoli ba ho beha qeto ea nako ea 'nete ho ntlafatsa maemo a sistimi le ho fokotsa nako ea phomolo.

Ka ho sebetsana le thepa e tsoetseng pele, indasteri e ka fihlela tlhahiso e phahameng le ho tsilatsila, e batla katleho ea nako e telele.

Tloaelo le Litharollo tse Ikopahetseng

Li-fiitits tsa Pneumatic

Liphetoho tsa Pneumatic litloa ka litlhokahalo tse ikhethileng tsa indasteri e fapaneng ka ho fana ka lithallo tse netefalitsoeng. Li-trits tsena li tloaelana le litlhoko tse ikhethang tsa ts'ebetso, li netefatsa ts'ebetso e nepahetseng le e lumellanang. Mohlala, indasteri e nang le litsamaiso tsa khatello ea khatello e matla e le hore re khone ho mamella maemo a feteletseng, a ntse a tsoela pele ho nepahala ka ho nepahala ho ntlafatsoang le ho nepahala ka nepo. Ho etsa tloaelo ho boetse ho eketsoa ho khetha ho khetha lintho tse bonahalang, moo mekhoa e bobebe le e sa khaotseng e ntlafatsa ho tšoarella le ho sebetsa hantle. Ka ho tsamaisa liketsahalo tsa pneumatic, baetsi ba lihlahisoa ba ka kopana le litlhoko tse tobileng tsa likopo tsa bona, matlafatsa ho tšepahala le ho fokotsa nako eo.

Mehlala e ikhethang ea indasteri e ikhethang

Tsheelo e bapala karolo ea bohlokoa liiestara e kang ho kenella, liroboto le aerospace. Ka ho boloka likhokahano tse sireletsehileng le tse bohlokoa, tse bohlokoa bakeng sa ho boloka maemo a sistimi. Hangata ho etsa lipatlisiso tse thusang ho tsamaisa taolo ea khatello ea moea le phalle, ho nolofatsa metsamao e nepahetseng le e sebetsang. Liindasteri tsa Aerospace li rua molemo ka li-gratives tse bobebe le tse kopane tse fokotsang boima ba 'mele ka ho fetisisa ntle le ts'ebetso ea ho seha kotsing. Mehlala ena e totobatsa hore na ho amme ho matlafatsa ts'ebetso ea ts'ebetso le tlhahiso ea litsamaiso tsa limela tsa limela ka ho 'na joang li ka ponahareng likarolong tse fapaneng.

Lintlafatso tsa katleho ka tloaelo

Mefuta e hlophisitsoeng e hlophisitsoeng e hlophiselitsoeng haholo e ntlafatsa matla a ts'ebetso ea ts'ebetso. Ka ho hlakisa taolo e nepahetseng ea khatello ea moea le phallo, lintho tsena li ntlafatsa ts'ebetso ea lits'ebetso tse ikemetseng. Morero ona o fokotsa litšila tsa matla ebe o ntlafatsa tlhahiso ea mechintery. Meralo e tšehali e boetse e nyenyefatsa moea o tlohang ho tlola melao ea matla a ho fumana chelete e ka bang 30%. Tafole e ka tlase e akaretsa ntlafatso ena:

| Karolo ea Ntlafatso | Lintlha tsa lipalo |

|---|---|

| Phokotso ea Matla a Energy | Ho fihla ho 30% |

Tsibization ha e felle feela ts'ebeliso ea matla empa e boetse e fetisa litšenyehelo tsa bophelo, litšenyehelo tsa ho fokotsa litšebeletso le ho netefatsa hore matšeliso a nako e telele.

Ho Kopana le Liroboto tsa Robotics

Li-Tokelo ea Pneumatic ho Tsamaiso e ikemetseng

Litokisetso tsa Pneumatic li bapala karolo ea bohlokoa litsamaisong tsa ikenya ka ho netefatsa khokahano e sireletsehileng le e sebetsang lipakeng tsa likarolo. Lintho tsena li tsamaisana le taolo e nepahetseng ea khatello ea moea le phallo, e bohlokoa bakeng sa ts'ebetso e ntle ea mochini. Likarolo tse kang tse ka tlase tsa mechini ea ho hokahanya le ho hokahana kapele ho nolofatsa lits'ebeletso tsa kopano le ho fokotsa nako ea phomolo. Mahlale a Magine Svies o ile a kopanngoa le likepe tsa Pneumatic ho matlafatsa ts'ebetso ea bona ka ho lekola nako ea nako ea sebele ea likarolo tsa sistimi ea 'nete. Khokahano ena e ntlafatsa ts'ebetso, e fokotsa litšenyehelo tsa ts'ebetso ea tšebetso, 'me u netefatse ts'ebetso e sa feleng libakeng tse sa feleng.

Lisebelisoa tsa liroboto

Liroboto li itšetleha haholo ka li-genematic ho fihlela sepheo le ho ts'epahala. Mefuta ena e tsamaisa motsamao o laoloang ea liroboto le likarolo tse ling ka ho tsamaisa khatello ea moea le phallo. Moralo o bobebe le ea bobebe o molemo haholo-holo liroboto, moo mathata a sebaka le maemo a tloaelehileng a bohlokoa. Mohlala, ho betla li-finematic li-grichetic li-grippers tse netefatsang tse hlakileng tsa lintho tse bonolo, li li etsa hore li ratehe liiries le bophelo bo botle. Bokhoni ba ho boloka ts'ebetso e sa feleng tlas'a maemo a fapaneng bo totobatsa bohlokoa ba bona ho tsoelang pele theknoloji ea robono.

Ho kopanya melemo bakeng sa ho kenella

Khokahano ea likhechana tsa li-vneumatic li e-ba mekhoa e ikemetseng e fana ka melemo e mengata. Metsoako ena e matlafatsa khatello ea tsamaiso ka ho thibela moea o tlolang le ho netefatsa maemo a kotsi a khatello. Tsamaiso ea likopano e potlakileng, e ile ea nolofalletsa meralo e loketseng, ho fokotsa nako ea tlhahiso le ho eketsa katleho e fetang ka kakaretso. Bo-'mè ba ho hlokomela nako ea 'nete ba lumella basebetsi ho tseba le ho rarolla litaba kapele, ho fokotsa litšenyehelo tsa nako ea nako ea nako. Ka ho ntlafatsa ts'ebetso ea ts'ebetso le tšebeliso ea matla a matla a matla, li-finematic li kenya letsoho molemong oa ho tsitsa le tšebeliso ea litšenyehelo tsa lits'ebetso tse ikemetseng.

Polokeho le litekanyetso tsa ho amohela

Ho latela melao ea indasteri ea indasteri

Ho latela melao ea indasteri ea indasteri ea indasteri e bohlokoa bakeng sa ho netefatsa polokeho le ts'epahalo ea litsamaiso tsa leqhoa. Melao ea taolo ea taolo e laola moralo, ho etsa le ho etsa le ho sebelisoa ha liketsahalo tse ncha tsa tlhahiso ho thibela liphoso le likotsi tsa tšebetso. Indasteri e itšetleha ka ho kenella, moo ho tsamaisa thepa ea pneumatic ho bapala karolo ea bohlokoa ho ho hokahanya likarolo le ho boloka ts'ebetso ea tsamaiso. Ho khomarela Melao ena ho etsa hore mekhoa eo e iketlileng e sebetsang ka nepo ha e ntse e eketseha ka likotsi.

Lintlha tsa Bohlokoa tsa Ho Etsahala ho Ngola:

- Tlhokahalo e ntseng e hola ea ho kenella indastering ea indastering.

- Tlhokahalo ea ho netefatsa polokeho le katleho hodima mochine o ikemetseng.

- Karolo e nyarosang ea karolo e tšoaeang e loketseng ho boloka katleho ea ts'ebetso.

Ka ho latela litekanyetso tsena, bahlahisi ba ka fana ka lihlahisoa tse kopanang le li-benchmark tsa polokeho mme ho fumana ts'epo ea bareki.

Mefuta e metle ea polokeho ea Poneumatic

Ho etselitsoe litholoana tse tsepamisitsoeng tse sirelelitsoeng ka polokeho ea ho mamella maemo a feteletseng le ho thibela liphoso tsa sistimi. Likarolo tse kang litiiso tsa bopaki bo matla, li-conssunion tse thibelang thepa e thibelang khatello ea khatello e matlafatsang ntlafatsa ho tšepahala ha tsona. Lintho tsena li fokotsa kotsi ea likotsi tse bakoang ke likotsi tsa moea kapa khatello ea maikutlo, e netefatsang ts'ebetso e sireletsehileng libakeng tse patehileng. Mohlala, indasteri e kang ea Boimabello ea Healthcare le Aerospace e rua molemo ka lifilimi tse bolokang ts'ebetso e ngata tlasa khatello e matla kapa mocheso mochesong. Meqapi e tsepamehileng e sa sireletsang lisebelisoa feela empa hape e boetse ea sireletsa basebetsi ba sebetsanang le litsamaiso tsa limela.

Ho latela le ho latela 'maraka

Ho latela melao ea polokeho le litekanyetso tsa boleng ho theha ho tšepa 'marakeng. Bareki ba etela lihlahisoa tse etsang hore ho be le litlhoko tse tšehang, kaha tsena li netefatsa ho tšepahala ebile ho phela bophelo bo bolelele. Baetsi ba ikemetseng ba khomarelang maemo a ho latela melao-motheo ba fumana pheletso ea tlholisano ka ho bontša boitlamo ba bona polokelong le boleng. Ho feta moo, ho latela melao ka ho tšoanang ho fokotsa monyetla oa litaba tsa molao le likhathatso tsa tšebetso, ho ntlafatsa botumo ba k'hamphani. Litokisetso tsa Pneumatic tse khotsofatsang li tlatselletsa ho hlalosoa ka botlalo ha lits'ebetso tse ikemetseng, li li etsa hore li be bonolo indastering ea kajeno.

Indasteri ea phetetso e loketseng e fetoha kapele, e khannoa ke mekhoa e kang ho kopanya lijana, katleho ea matla le bophahamo. Ho qaptjoa ka thepa le mekhoa ea tlhahiso e tiisa hore ho tšoarella le ho ikamahanya le maemo likarolong. Tafole e ka tlase ho mekhoa ea lintlha tsa bohlokoa e bopang 'maraka ka 2025:

| Tloaelo | Tlhaloso |

|---|---|

| Ho Romella Ho Atleha ha Lisomi tsa Pentems tsa Smart Pneumatic | Khokahano ea Litsebi tsa Sensors le IOT bakeng sa tlhokomelo ea nako ea sebele le tlhokomelo e boletsoeng esale pele, ntlafatsa ts'ebetso ea tsamaiso. |

| Ho tsepamisa maikutlo ho katleho ea matla | Tlhokahalo ea lintho tse betliselitsoeng ho fokotsa moea le ho fokotsa tšebeliso ea matla, e khannoang ke ho tsitsisa le ho boloka chelete. |

| Keketseho ea Liteko le Litokelo Tse Ikhethileng | Baetsi ba fana ka mefuta e pharalletseng ea litšoaneleho tse atlehang ho fihlela litlhoko tse ikhethileng tsa indasteri, ba tšehetsoang ke tsoelo-pele joalo ka khatiso ea 3D. |

| Ho amohela thepa e tsoetseng pele | Khetho ea li-compotes tse tsoetseng pele le li-polymers bakeng sa boima bo fokotsang boima le ho tšoarella, ho lumella li-coivies ho mamella maemo a feteletseng. |

| Ho Minaudization ea likarolo tsa pneumatic | Tlhokahalo ea ho iphelisa e nyane, e sebetsang hantle ka lisebelisoa tse rarahaneng, haholo-holo ka litheolelo tsa motlakase le tsa bongaka. |

| Katoloso ea Channel ea E-Commerce | Keketseho ea li-pnemats tsa inthanete bakeng sa ho fumana habonolo ho fumana liketsahalo tsa bocha, ho ntlafatsa khatello ea lichain. |

| Matla a polokeho le litekanyetso tsa ho lumellana | Litlhokahalo tse eketsehileng li khanna ho khanna ho hlophisoa le lisebelisoa ho kopana le litekanyetso tsa tikoloho tse phahameng. |

Ho lula ho le bohlokoa bakeng sa ho boloka tlholisano sebakeng sena se matla. Liindasteri li tlameha ho latela tsoelo-motheo ena ho ntlafatsa ts'ebetso le ho fihlela lipakane tse matlafatsang. Ho lula tsebong ka mahlale a ts'ebetso a etsa hore likhoebo li lule nakong ena e fetolehang.

LBH

Lihopotso life li thusa haholo ho tsoa ho li-gneumatic?

Li-Tittings tsa PneumaticHo bohlokoa molemong oa lihlahisoa, oa bophelo bo botle, Aerospace le liroboto. Liindasteri tsena li itšetleha ka taolo ea moea e nepahetseng bakeng sa ts'ebetso e sebetsang le e tšepahalang.

Khokahano ea Iota e ntlafatsa joang litsamaiso tsa Pneimatic?

IOTRAION e thusa ho lekola nako ea nako ea 'nete le ho reha tšebetsong. Sena se fokotsa nako ea nako ea phomolo, e ntlafatsa katleho, 'me e tiisa ts'ebetso e nepahetseng ea tsamaiso.

Keletso: Ho tsetela ho li-ioli tsa li-vneumatic li-vneumatic li ka khona ho sebetsa haholo ka nako e telele.

Li lumellana le li-cenematic tse tšoarellang e le tse tšoarellang joaloka tsa maemo a tloaelehileng?

Ee, ho ikoetlisa ka kopanelo Sebelisa lisebelisoa tse tsoetseng pele le boenjiniere ho tla lula. Ba sebetsa ka mokhoa o sa feleng le libakeng tse tsitsitseng tsa sebaka kapa tse phahameng.

Nako ea poso: Mar-29-2025